What Is Modbus and What Is It Used For?

Modbus is a communication protocol used in the industrial automation sector. It was developed by Modicon (now Schneider Electric) in 1979 primarily for communication with programmable logic controllers (PLCs). The protocol defines the format and rules for exchanging data between devices over a serial connection.

There are several versions of the Modbus protocol, including Modbus TCP, Modbus RTU, Modbus ASCII, and Modbus Plus. These variations cater to different communication mediums and network topologies, such as Ethernet, serial ports, and fieldbus networks.

Modbus TCP is used for managing and controlling automation equipment over Ethernet networks. It operates similarly to Modbus RTU, which is designed for serial communication between devices. Modbus ASCII is another variant that converts instructions into ASCII characters for transmission, albeit less efficiently than Modbus RTU due to its larger message size.

How Does It Work?

Modbus functions on a master-slave architecture where a master device initiates communication with one or more slave devices. The master sends requests to read or write specific data points in the slaves, which respond accordingly. Messages follow a structured frame format, including address and function code fields, ensuring clear communication between devices. In serial communication, data is transmitted bit by bit over physical media, while in Ethernet-based communication, TCP/IP networks are utilized. Modbus defines various function codes for different operations, such as reading registers or writing data, facilitating diverse industrial automation tasks. Error detection mechanisms like CRC or checksum fields ensure reliable transmission, making Modbus a widely used and trusted protocol for real-time communication in industrial settings.

How Is Modbus Used In The Industry?

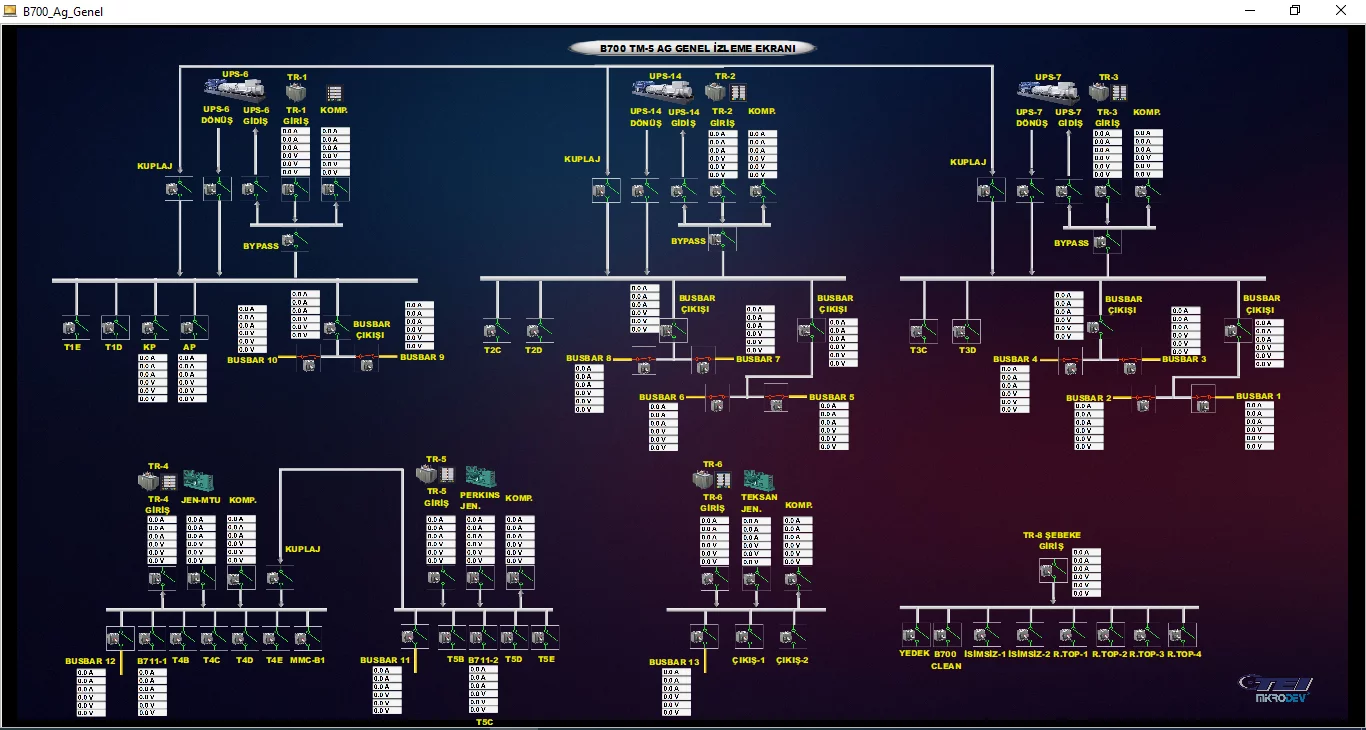

Modbus serves as the backbone of communication for a myriad of processes and systems. Its versatility and robustness make it a go-to choice for integrating disparate devices, ranging from sensors and actuators to PLCs and SCADA systems. One of the primary applications of Modbus is in data acquisition, where it facilitates the collection of critical data points such as temperature, pressure, and flow rates from various sensors distributed across the production floor. This data is then transmitted efficiently over serial lines or Ethernet networks to central control systems for analysis and decision-making, enabling real-time monitoring and optimization of industrial processes.

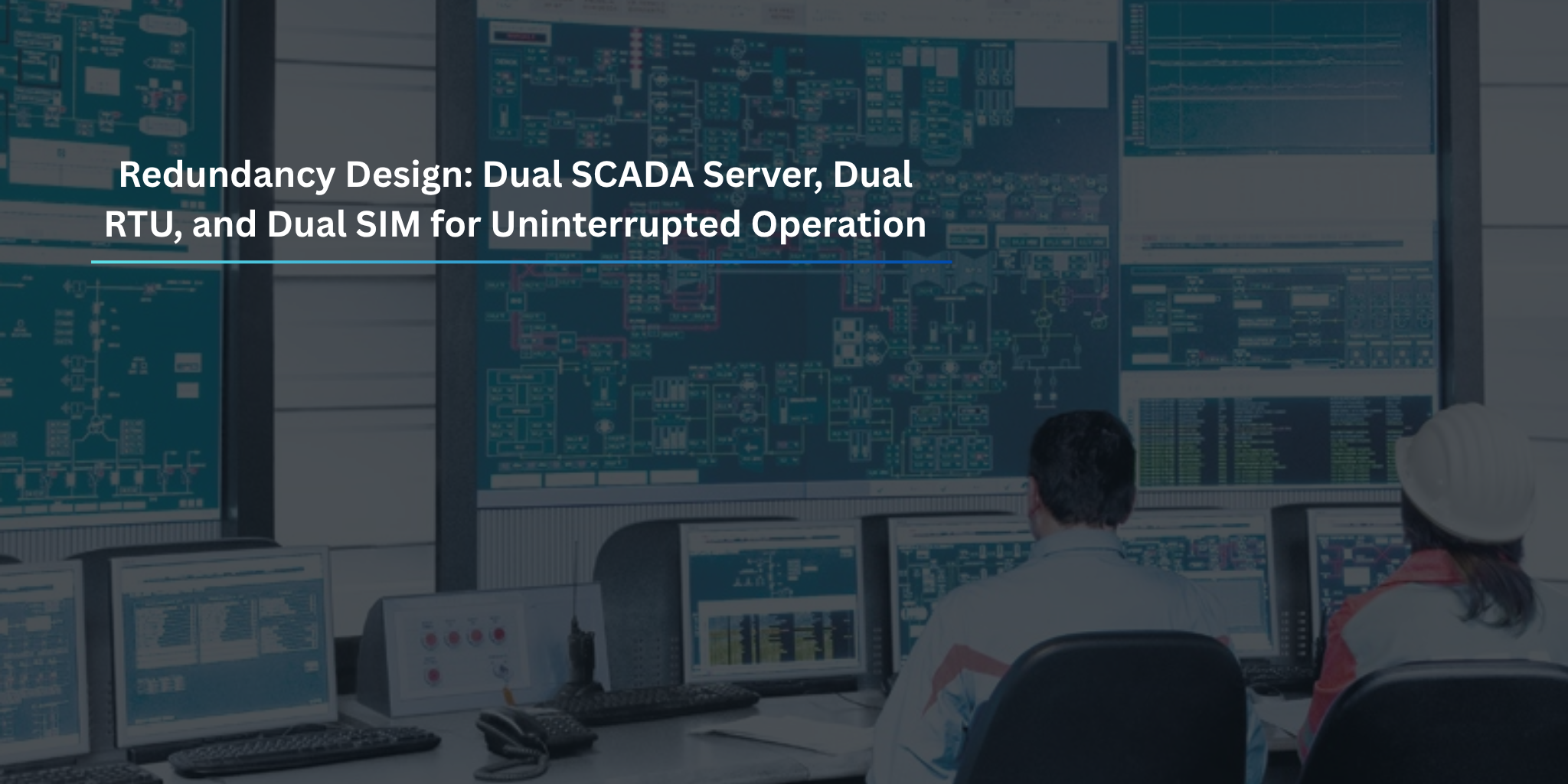

Moreover, Modbus finds extensive use in supervisory control and data acquisition (SCADA) systems, where it acts as the communication protocol between RTUs and PLCs and the central SCADA software. This integration allows for comprehensive monitoring and control of industrial operations, ranging from equipment status and performance to alarms and alerts for potential issues. Modbus’s reliability and simplicity make it well-suited for mission-critical applications in industries such as manufacturing, energy, and utilities, where uninterrupted communication and data exchange are paramount for ensuring operational efficiency and safety. Overall, Modbus’s ubiquity and adaptability have cemented its position as a cornerstone technology in industrial automation, driving innovation and optimization across diverse sectors.

Frequently Asked Questions

Is RS485 and Modbus same?

RS-485 is a physical layer standard for serial communication, while Modbus is a protocol that defines the format and rules for exchanging data between devices.

What is difference between Modbus and Ethernet?

Modbus is a communication protocol used for serial communication, while Ethernet is a network protocol used for transmitting data over local area networks (LANs).

Why is Modbus still used?

Modbus is still used due to its simplicity, reliability, and widespread adoption across industrial automation applications.

Is Modbus an Ethernet?

Modbus can run over Ethernet, but it is not inherently Ethernet itself. MODBUS TCP communication can be used via ETHERNET.

These blogs may interest you:

- MODBUS TCP Protocols and Applications in Mikrodev PLC Devices

- Increasing Efficiency: Using MODBUS Gateway in PLC Programming

- Comparison of MODBUS and IEC 60870-5-104 Communication Protocols