What is MODBUS Protocol and Its Features?

Modbus protocol is a serial communication protocol used to communicate between devices in industrial automation systems. Below you can find information about the main features and components of the Modbus protocol:

Protocol Types

- Communication Protocol: Modbus is used as a serial communication protocol. It enables data transmission between devices over physical communication lines such as RS-232, RS-485.

- Master-Slave Structure: Modbus communication is generally based on a Master device sending commands and exchanging data to one or more Slave devices.

- Modbus RTU ve Modbus ASCII: The Modbus protocol comes in two main formats: RTU (Remote Terminal Unit) and ASCII (American Standard Code for Information Interchange). RTU provides communication in binary format and is generally faster. ASCII is a human-readable format.

- Data Package Structure: In Modbus communication, data is sent in packets following a specific format. These packages include sections such as header, function code, data field and CRC (cyclic repeat check).

- Function Codes: There are function codes used to specify different operations in Modbus communication. For example, code 03 is used for a data read request, while code 06 is used for a write request.

- Addressing: In Modbus communication, each device has an address. The master device recognizes and communicates with the slave device it wants to communicate with via this address.

- Multiple Device Support: Modbus supports multiple devices on the same data line. This facilitates multi-device structures used in industrial automation systems.

- Error Management: Mechanisms such as CRC are used for error management in Modbus communication. CRC is an error checking algorithm used to ensure the accuracy of transmitted data.

These key features make the Modbus protocol a popular choice in industrial automation and control systems.

Modbus Communication Protocol

Modbus is based on Master/Slave architecture. Every Modbus application has at least one Master and at least one Slave. Master communicates with and controls Slave devices.

MBAP (Modbus Application Protocol Header) Header Structure

Transaction Identifier: The process identifier determines communication between two devices.

Protocol Identifier: Protocol identifier, takes the value 0 for Modbus.

Length: Determines the data length.

Unit Identifier: The volume identifier identifies the remote volume in the system.

Modbus TCP/IP PDU Section

Function Code:Indicates the action requested or responded to in the transaction.

Data Section: It contains transaction-related data and is of variable length.

Data Storage Structure

Data is stored in four different tables: two tables store on/off status values (coils), the other two store numerical values (register). It should be noted that each chart has a different offset.

Slave ID ve Function Code

Each Slave has its own address number and this address information is sent when a data request is made.

Function Code is a number sent by the Master that indicates what action the Slave will perform.

Modbus protocol is a communication protocol widely used in industrial automation systems. It provides efficient and reliable communication in industrial applications by providing communication via serial communication and Ethernet.

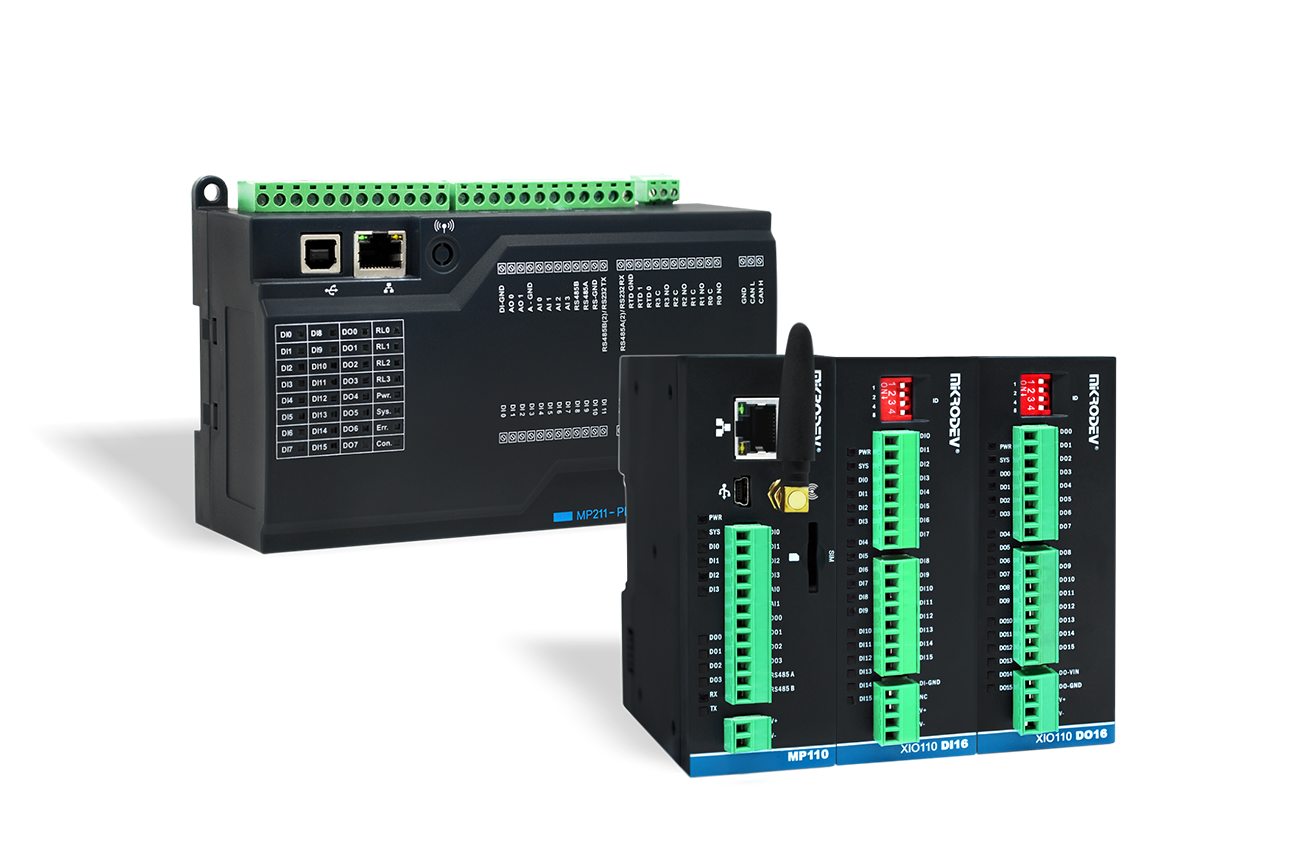

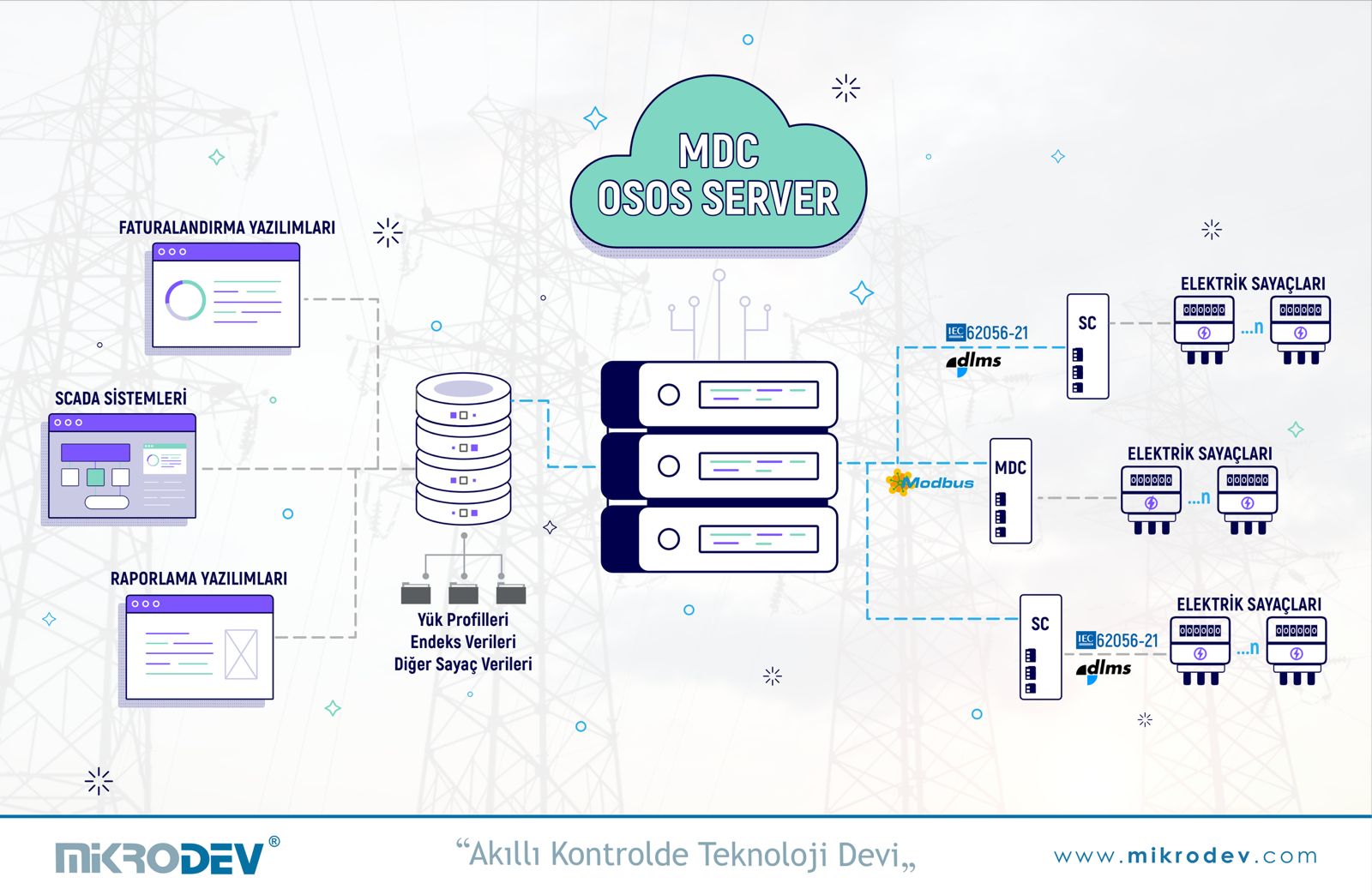

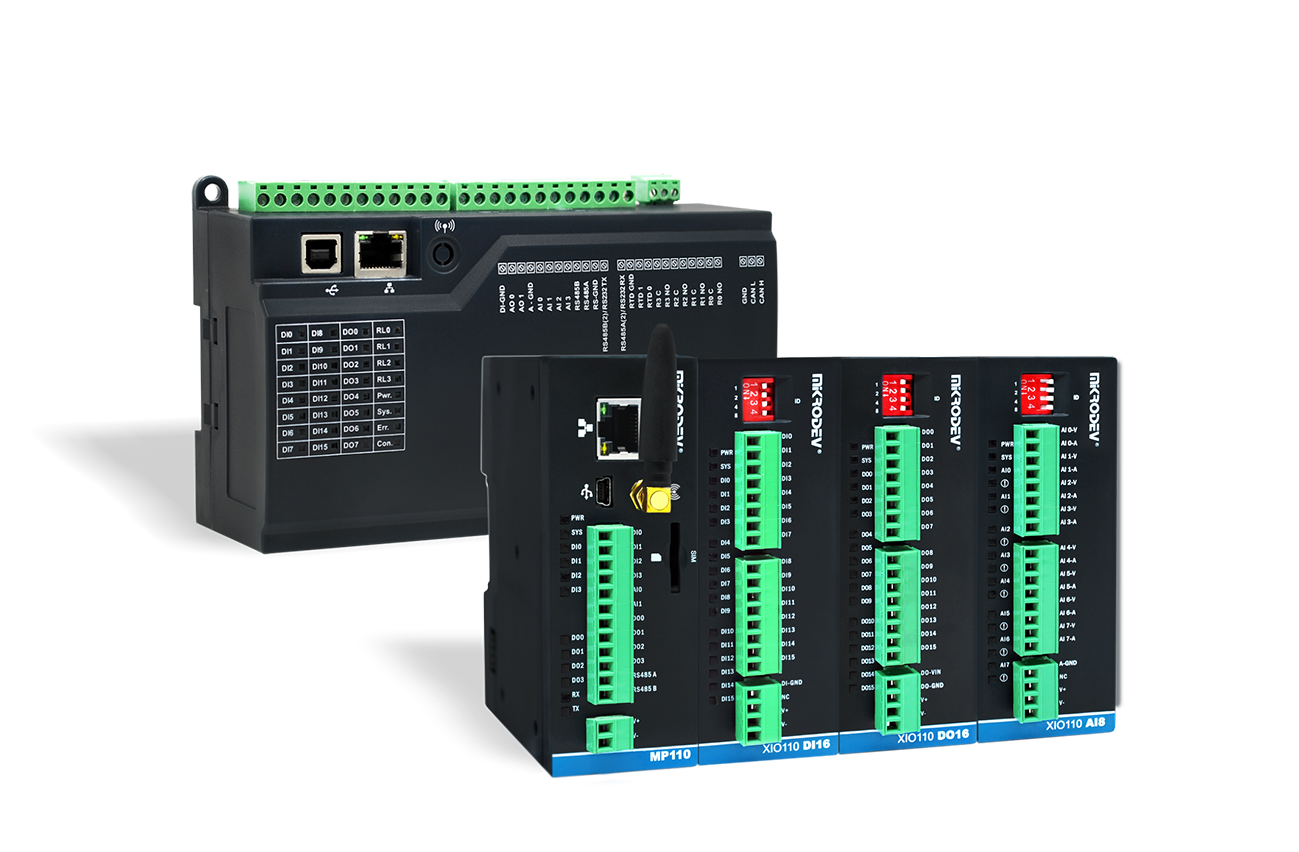

Reliable Solution in Industrial Automation, Mikrodev’s Modbus Products

Mikrodev’s Modbus products are designed to perfectly meet the communication requirements in industrial automation systems. The IoT Protocol Converter and Gateway Solutions include MBS100 Modbus, MMS100 MBus, and the MDC100 Series DLMS MODBUS Gateway.

They stand out with their reliability and superior performance. Mikrodev’s innovative solutions are an ideal option to increase efficiency and optimize data collection and analysis processes in industrial facilities. Additionally, with their user-friendly interfaces and easy integration features, they provide a seamless transition for systems using the Modbus protocol. Mikrodev’s Modbus products hold a leading position in the field of industrial automation by focusing on reliability, performance and ease of use. By choosing Mikrodev’s high-quality Modbus solutions, you can meet the communication needs of your industrial business at the highest level.