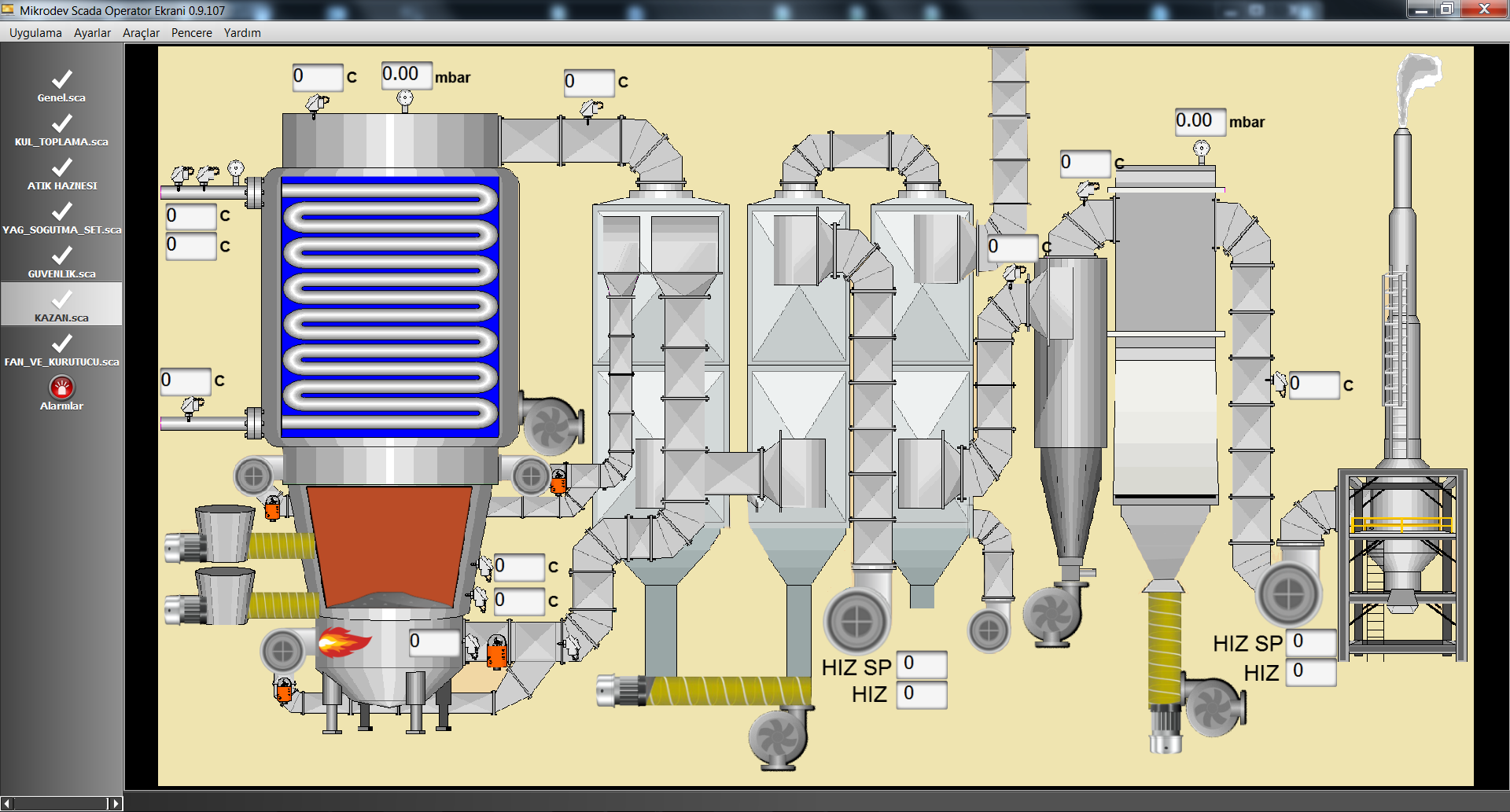

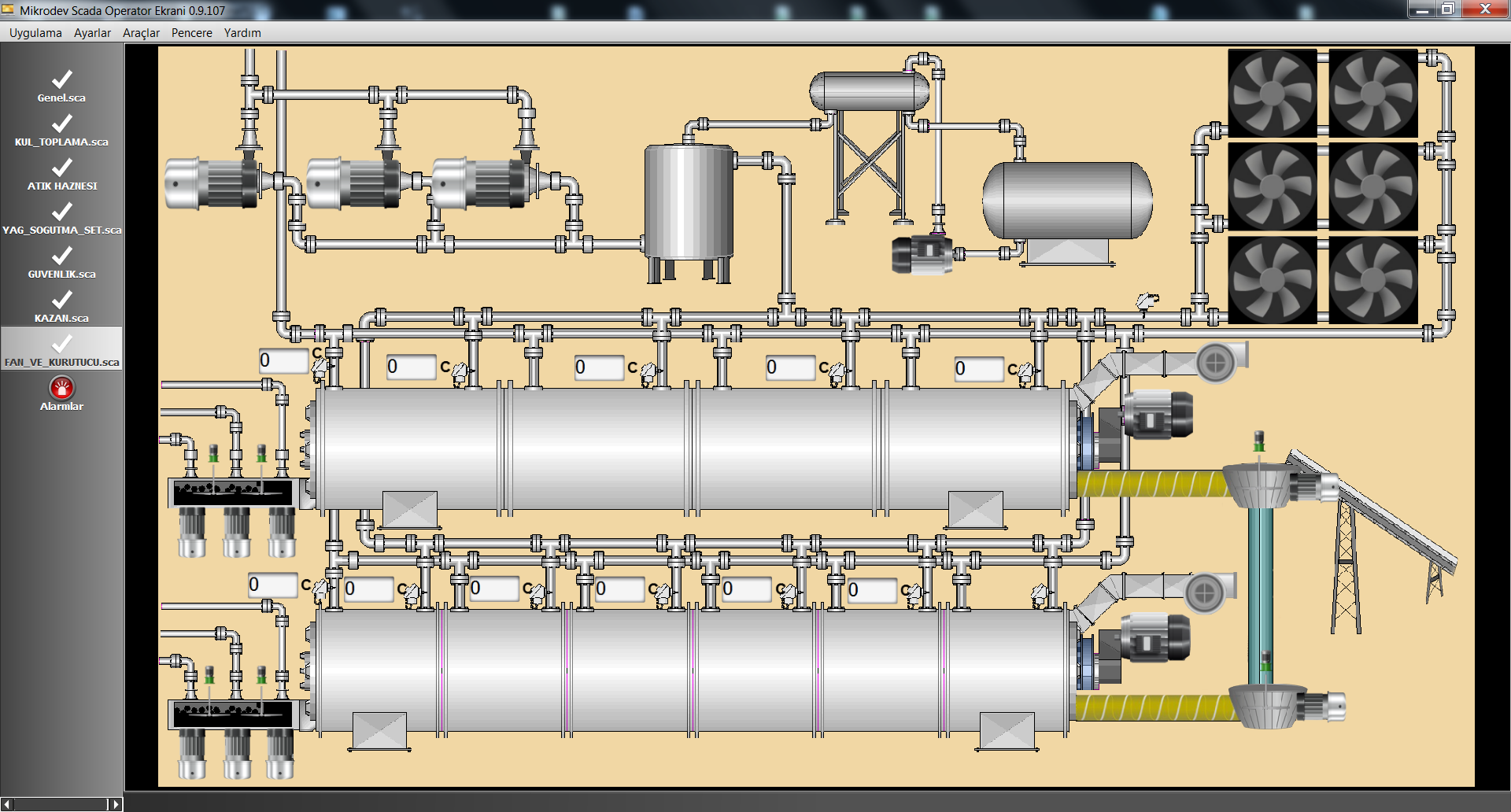

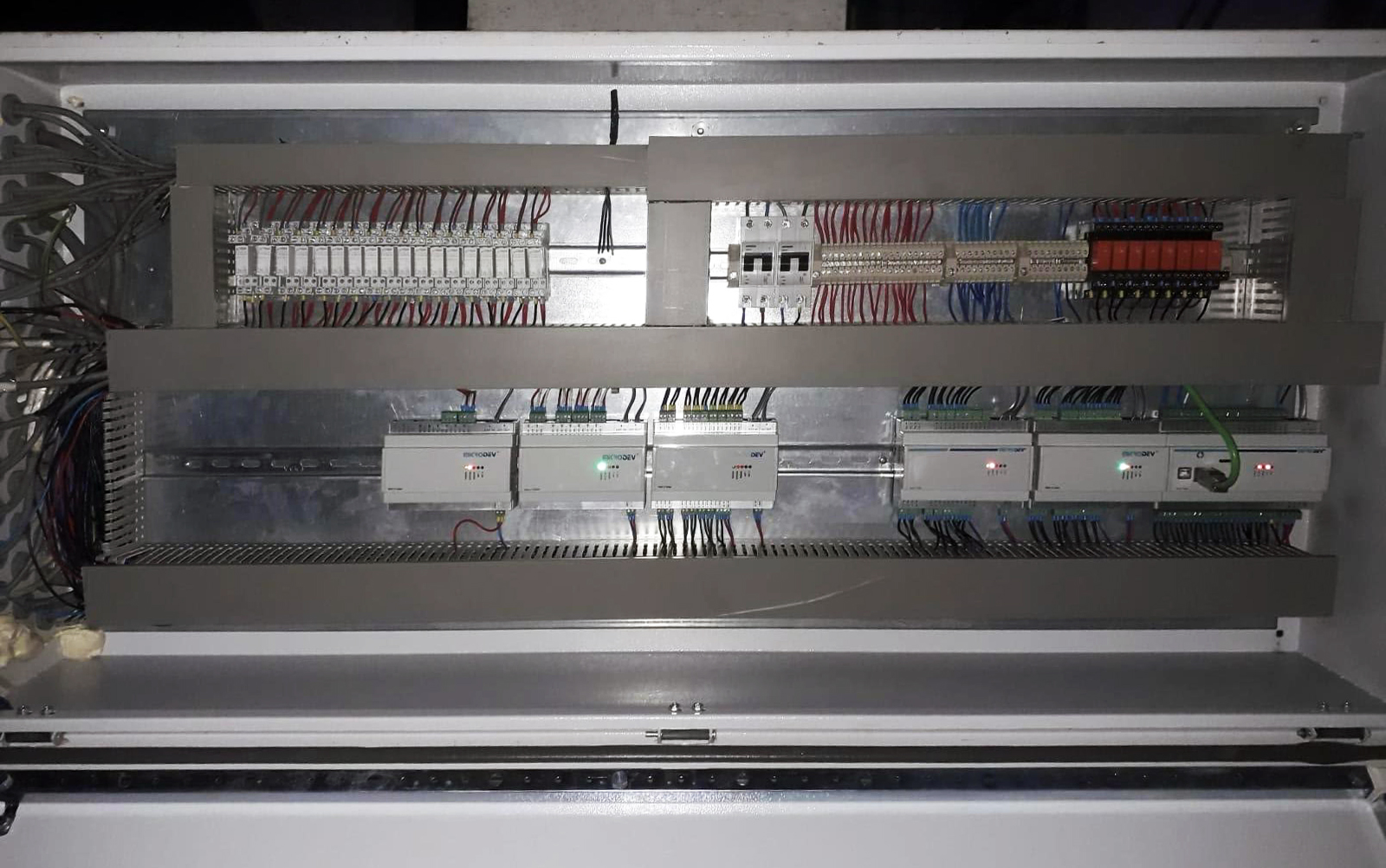

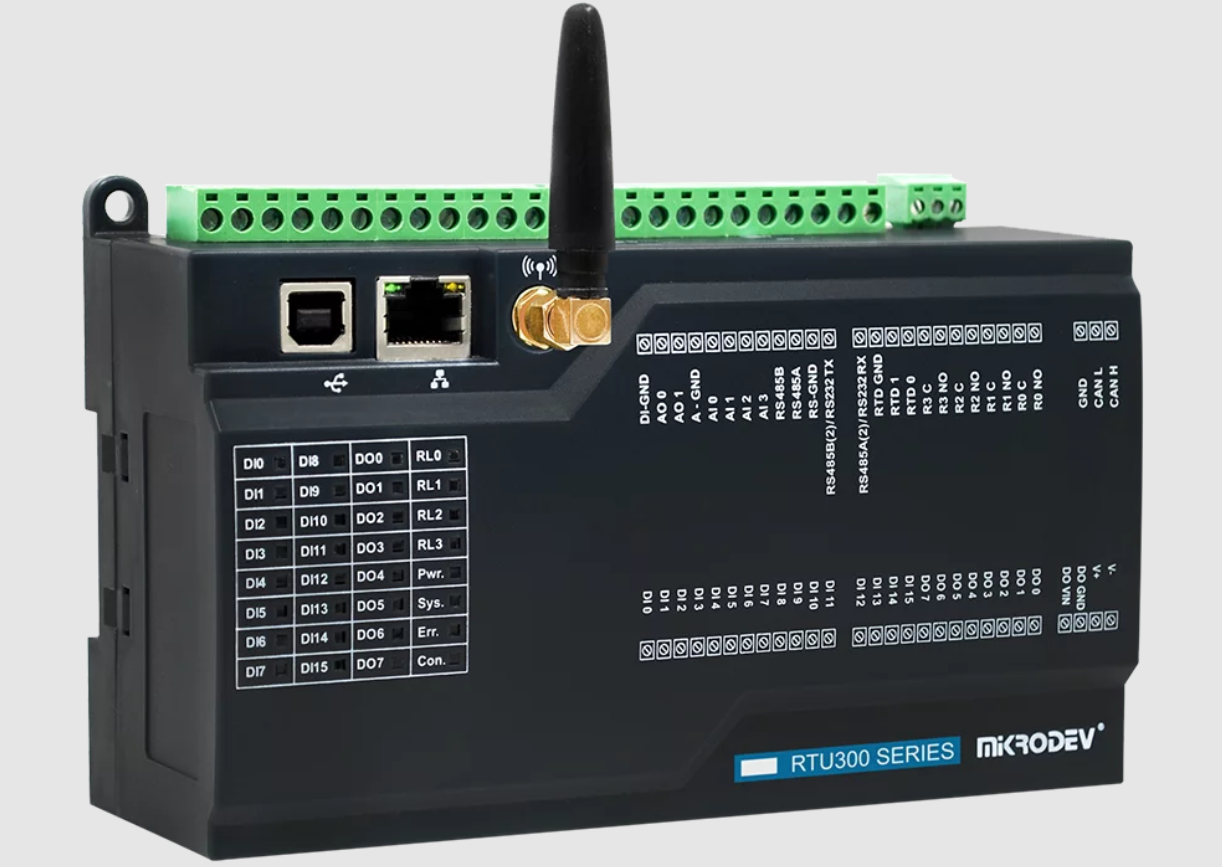

Mikrodev PLC products were preferred in the follow-up and control of the processes of Türkiye’s first sludge incineration plant in Gaziantep. The process is carried out at 850 to 1100 degrees Celsius. In this way, energy is produced. Mikrodev products continue this operation successfully in high temperature and harsh conditions.

- The first sludge incineration plant in Türkiye

- Over 600 physical and analog I/O signals

- 2000 data control via ViewPLUS SCADA170 tons/day of treatment sludge coming out of the wastewater treatment plants of GASKİ is collected in the sludge tank and sent to thermal drying with the help of transmission equipment

- Burning process is carried out between 850 and 1100 degrees

- With the turbo drying system, the waste sludge is dried and burned, while the heat released during the incineration meets the energy needs of the drying system, efforts to generate electrical energy from residual heat continue

- The resulting ash; It is used in asphalt, cement or plastic industry

- The gas released during the combustion process is converted into electrical energy by the biogas cogeneration unit. In this way, the facility produces 80% of its electricity need

- Alarm tracking

- Daily, monthly, annual reporting on a station basis

- Access to reports via Web Server