SCADA Systems and Their Role in Automation Processes

SCADA systems (“Supervisory Control and Data Acquisition”) are comprehensive and centralized automation systems that enable the control and monitoring of industrial processes. SCADA assists businesses in managing their production processes effectively in industries such as energy, water management, petrochemicals, food & beverage, manufacturing and transportation. In this article, we will discuss the scope, application areas and benefits of SCADA systems in automation processes within the scope of different topics.

What is the SCADA System?

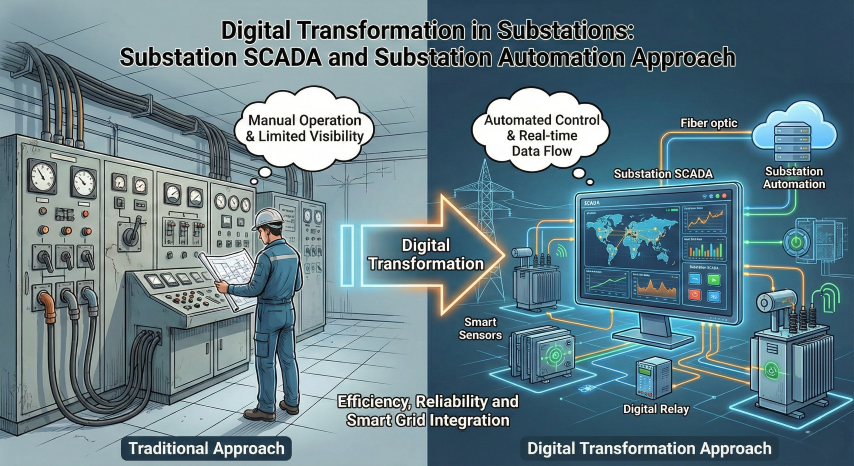

Technically, SCADA is an advanced industrial measurement and control system that comprises a central host or master, operating in data acquisition and control units in one or more fields, or consists of a collection of standard and custom software used for remote monitoring and control of devices and data elements. In this sense, SCADA software primarily performs monitoring, control, data collection, data recording and storage functions. The term SCADA stands for Supervisory Control And Data Acquisition, which highlights its focus on the supervisory level rather than being a comprehensive control system.

In this context, SCADA systems can be described as an automation system used for monitoring and controlling industrial processes. SCADA systems are used for real-time data collection, process control and process optimization. The systems manage and process data exchange between distributed hardware and software components through a central computer. These components carry out control and monitoring functions, thus ensuring the processes operate healthily and efficiently.

The Industries Using SCADA Systems

Today, SCADA systems are actively used in various applications in the industrial fields. The main ones include energy management, natural resource management, transportation and manufacturing industries, clean water and wastewater management, which are closely related to our daily lives. SCADA systems are high-tech engineering solutions essential for maintaining the normal flow of life in the 21st century.

Energy: SCADA systems are adopted in areas such as electricity transmission and distribution networks, renewable energy, energy management and energy production facilities. These systems provide more effective control and efficiency in energy production, transmission and distribution.

Drinking Water and Wastewater Management: SCADA systems are applied in areas such as drinking water supply and treatment, wastewater treatment, water networks and irrigation systems. This allows for more efficient and reliable management of the limited water resources and infrastructure in our world.

Petrochemicals and Gas: SCADA systems are significantly utilized in the petrochemical and gas industry, such as refineries, gas distribution and storage facilities and pipeline monitoring and control. These systems provide the necessary controls for safe and effective processing and transportation of hazardous materials.

Food and Beverage: Integrated SCADA systems are also used in food and beverage production, packaging and storage facilities, which are more closely related to our daily lives. The systems support the production of products at appropriate standards by increasing the efficiency and quality of production processes. They also significantly prevent human errors in manufacturing.

Manufacturing: In manufacturing sectors such as automotive, textiles, chemicals and metallurgy, SCADA systems have become standard technological solutions, especially in developed countries. These technologies are of critical importance in optimizing all production processes in facilities and providing superior product quality.

Transportation: SCADA systems are widely preferred in transportation infrastructure such as airports, ports, railways and highways. These systems enable more competent and systematic execution of processes such as traffic management, security and infrastructure maintenance.

Advantages of SCADA Systems for the Automation Industry

SCADA systems used to monitor, control and manage processes and systems in the automation industry play a key role in increasing the efficiency of operations, reducing costs and optimizing production processes. The advantages offered by SCADA systems in the automation industry can be explained as follows:

Real-Time Data Collection and Monitoring: SCADA systems continuously collect data from industrial processes and analyze this data instantly, providing real-time monitoring capabilities. The collection and analysis of real-time and historical data help evaluate and improve the performance and quality of processes. By means of that, operators can continuously monitor the status of processes and intervene when necessary.

Remote Control and Management: As we underlined several times, SCADA systems enable the remote control and management of industrial processes. This allows operators to control and manage processes without the need to be physically present at the site. This helps businesses reduce labor and energy costs. After the Industry 4.0 revolution, the importance of remote access and management systems has increased irreversibly and solidified their place in processes globally.

Alarm & Event Notification: SCADA systems enable the rapid and effective detection and management of abnormal situations and processes. With these systems, abnormal situations or events that occur in processes can be detected; additionally, automatic alarms and notifications can be sent to warn operators. This provides timely intervention possibilities, contributing to the more reliable and stable operation of systems. Consequently, real-time crisis management becomes easier and can even settle into a specific system.

Data Analysis & Reporting: SCADA systems allow the analysis of collected data, evaluating process performance and offering improvement suggestions. In addition to this, they can prepare detailed reports to help businesses better understand and manage their processes. Real-time monitoring and control of processes in this manner increase the efficiency and reliability of production stages.

Energy & Resource Usage Optimization: As mentioned, SCADA systems closely monitor energy and resource usage, contributing measurably to businesses’ energy and resource savings. This optimization capability supports sustainability criteria, a priority component of our age, in many industrial areas.

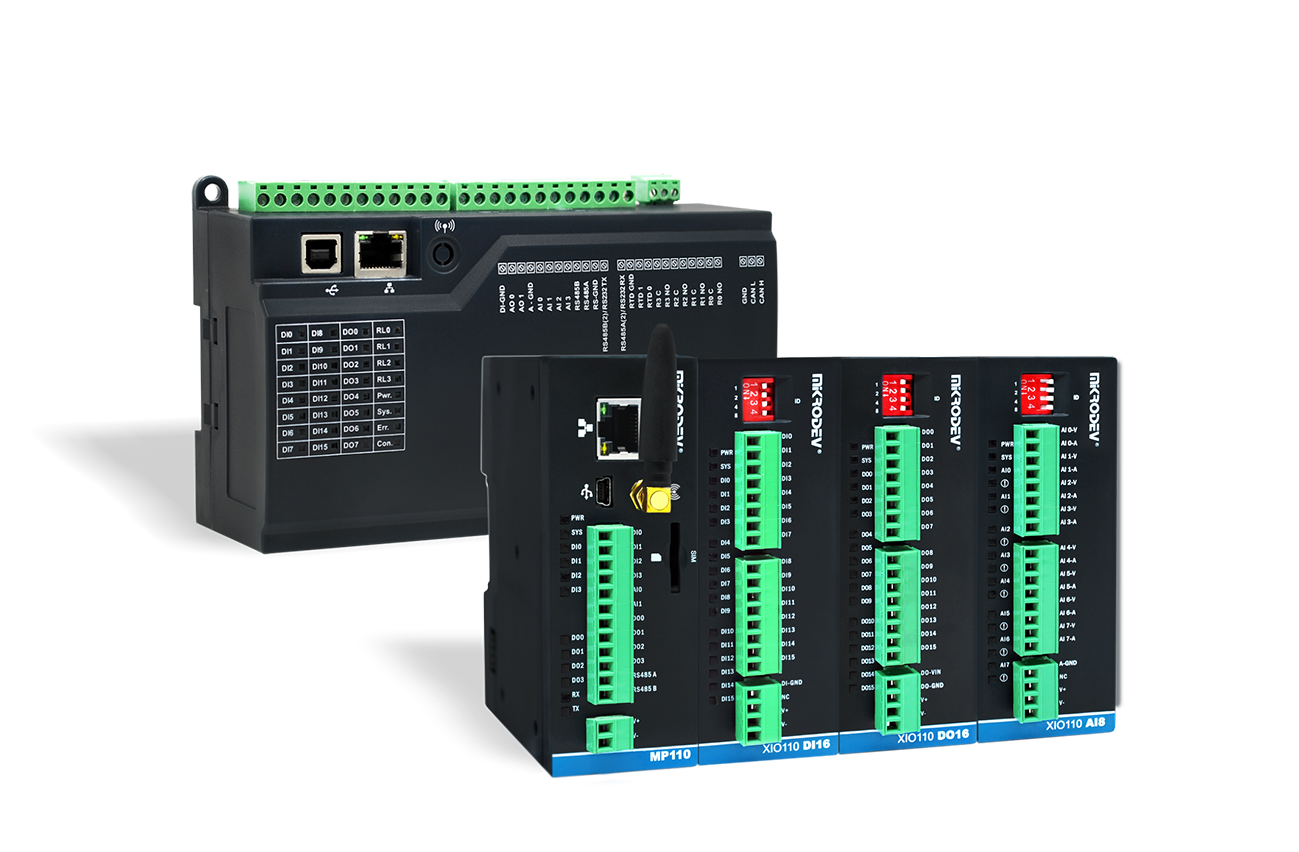

Protocol Integration: SCADA systems can communicate compatible with industrial communication protocols such as Modbus TCP, MQTT, IEC104, DNP3 through Mikrodev’s local PLC and local RTU products. They also enable different devices and systems with these protocols, regardless of the brand, to work together. This contributes to the flexible and modular structure of industrial processes.

Advantages of Using SCADA Systems in Water Treatment & Wastewater Automation Systems?

Up to that point, we have discussed the general applications and advantages of SCADA systems in industrial areas. In this section, we will focus on the advantages of using SCADA systems in wastewater automation systems, which are listed among vital infrastructure applications in cities and developed urban areas.

As in different industrial areas, utilizing SCADA systems in drinking water management and wastewater treatment plants has become quite important for more efficient, safe and sustainable automation. The advantages of using SCADA systems in drinking water treatment systems and wastewater automation can be listed within the criteria mentioned above as real-time monitoring, remote access and control, alarm and event notification, data collection and analysis and energy & resource optimization. Additionally, the use of SCADA in drinking water treatment and wastewater facilities supports more flexible and compatible operation of processes by providing integration between different equipment and processes throughout the facility. Moreover, the use of SCADA systems in water management systems simplifies the operation and maintenance of water management facilities. This allows businesses to manage their processes faster and at lower costs.

Mikrodev’s SCADA Systems & Solutions for Water & Wastewater Systems

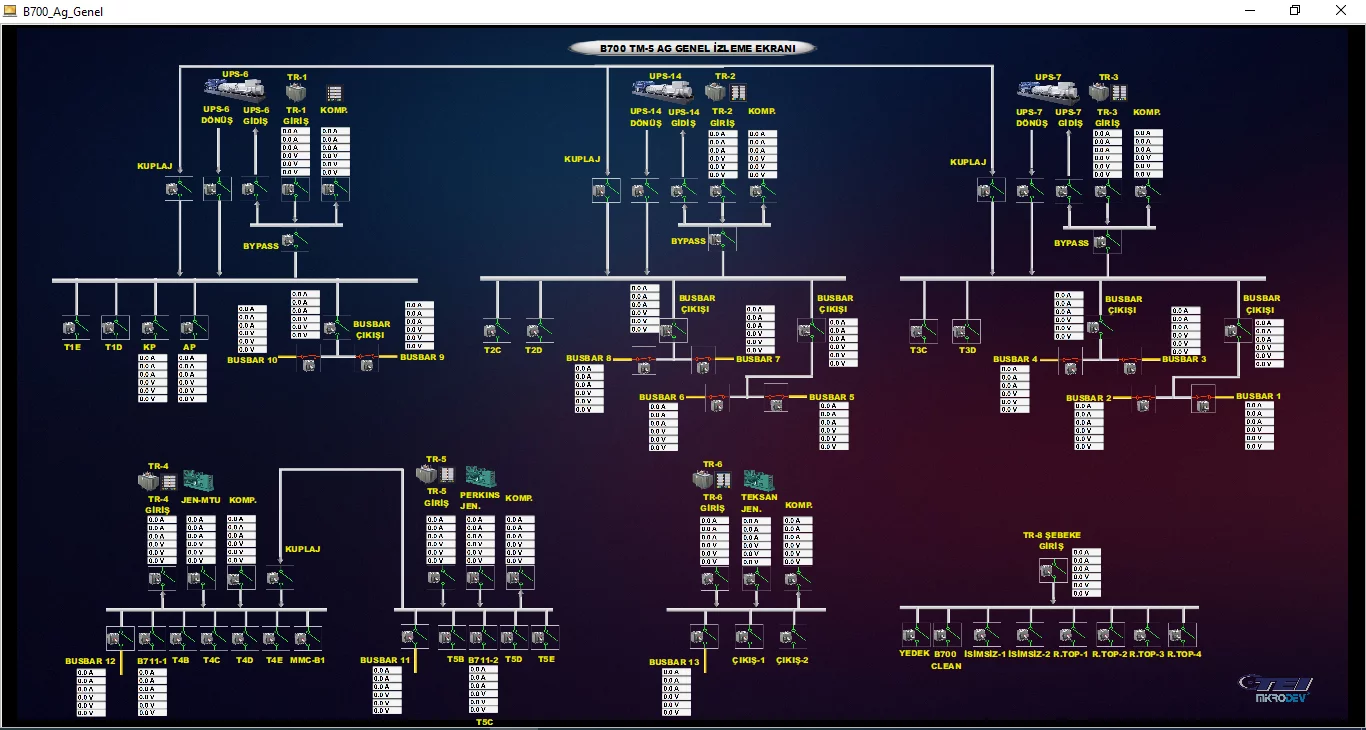

Mikrodev’s SCADA systems and solutions for water and wastewater systems

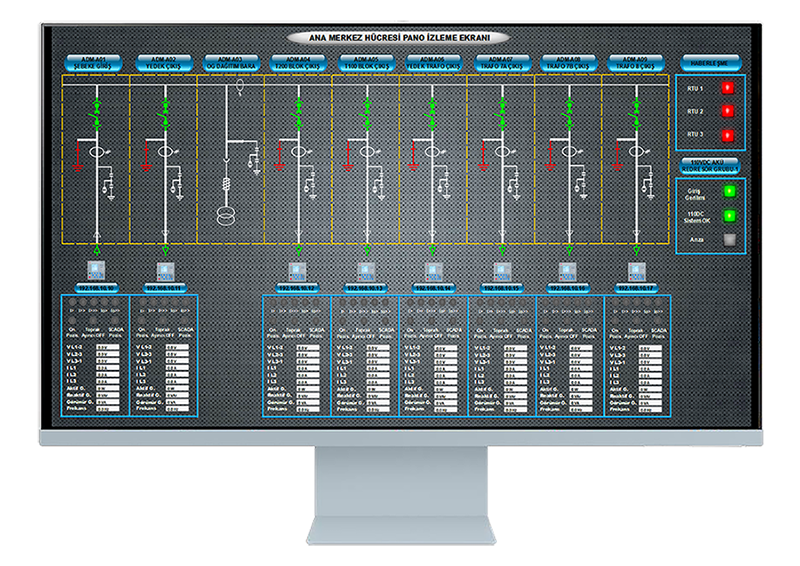

offer a range of additional advantages for effective and sustainable water management. In Mikrodev SCADA systems, in which ViewPLUS SCADA software is used, the parameters in the water treatment process are monitored, controlling not only the quality of water but also its distribution and storage. The collected data can be monitored and reported daily, weekly, monthly and annually. Pump valve auto/manual controls and possible alarm tracking of field equipment are also carried out through the system. Thanks to graphic map support, the system can be monitored live on a map.

In this context, the effectively utilized Mikrodev SCADA system reduces operating costs in water treatment plants and increases operational efficiency. Since the SCADA system controls the distribution and storage of water, it supports the more efficient use of water resources for businesses as well. As a result, drinking water and wastewater treatment SCADA systems have become a vital tool in both industrial applications and considering water resources.

In addition to these advantages, Mikrodev’s native SCADA solutions stand out with their customizability and integration capabilities. Mikrodev’s SCADA systems can be tailored to drinking water treatment and wastewater management processes, making it possible to generate flexible and compatible solutions for effective water management in different industries and facilities. Moreover, integration between different equipment and processes throughout the facility elevates the optimization of water treatment processes. Mikrodev’s SCADA systems, providing real-time monitoring and control in drinking water and wastewater management, enable continuous performance analysis and evaluation, promptly notifying situations requiring rapid intervention.

Mikrodev SCADA solutions, which ensure the safe operation of water management processes in terms of energy and resource optimization and remote access, serve Turkey’s automation processes development using native technology. Please visit the webpages for Mikrodev SCADA solutions operated in water and wastewater systems, in order to reach a sustainable solution for your business using Mikrodev products.

Below, you can find some of the large-scale drinking water SCADA systems and wastewater SCADA system management applications projects Mikrodev has implemented so far :

- Gaziantep City Water and Sewerage Administration (GASKI) Drinking Water Disinfection SCADA System

- Republic of Türkiye General Directorate of Agricultural Enterprises (TIGEM) Pivot Arm Irrigation, Fertilizing & Seed Dressing SCADA System

- Turkish Armed Forces Base Areas Water Distribution System

Tekirdag City Water and Sewerage Administration (TESKI) Water Distribution SCADA System - İstanbul Metropolitan Municipality Smart City SCADA System

- Mugla City Water and Sewerage Administration (MUSKI) Water SCADA System